This post is about how we go about finding the right fit for each client regardless of whether they are spending $15,000 on a custom carbon road bike or $1800 on a stock-sized steel hardtail mountain bike.

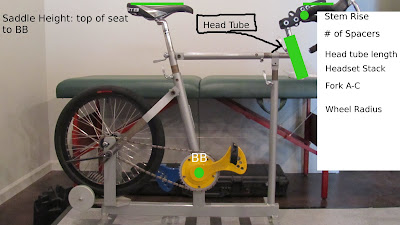

In the picture above is an size XS Wilier Izoard XP -- a $2500 carbon road bike. Behind it is a Size Cycle; which is an adjustable bike we use to mock up various positions to see what the best fit is. We can then take these raw contact points -- where the seat is relative to the bottom bracket, where the bars are then placed as far as reach and height, as well as the proper crank length. If a client is interested in a particular bike, like this Wilier, I will mock up that bike's contact points on the Size Cycle and test from there.

Why not just get them on the Wilier to start? Sometimes I do, but the Size Cycle allows for quicker adjustments, and makes it more likely we're going to settle on the best fit for that client, not just the best fit that's possible on that bike. There are times, like with a client that came in last week, where the bike they were interested in would not provide the best fit, even with drastic alterations to it's components. On the size cycle, we aren't limited by the bike, because all it's dimensions are adjustable. To make the reach longer or shorter, I can change:

- the effective top tube length

- the seat angle

- the saddle fore-aft

- the stem length

- the bar reach

- and even the head angle (which changes how much reach the stem has).

- the saddle fore-aft

- and the stem length

So the first thing we get out of the way using the Retul infrared motion capture system is the saddle height and it's set-back from the bottom bracket. While the set-back is important because it relies on the seat angle of the bike -- something that is not changeable once we have an actual bike under the client -- the saddle height is not of huge consequence because it is by far the most adjustable aspect of the bike via seatpost adjustment. (we do still need to consider things like what shoes and cleats the client will use since the overall seat height plays directly with the overall saddle to bar height differential -- how much the bars are above or below the saddle).

After we determine the saddle height we begin on the reach and height of the bar. Using the Retul, we can again make adjustments to find the optimal bar position. We have to take into account the client's riding history (do they get numb hands, neck pain, low back discomfort?) as well as their medical history (have they had any orthopedic surgeries? leg length issues?)

Once we have them comfortable and efficient, then I start with the 7th grade math and trigonometry.

What is my aim? Basically to take this bar position (it's height from the ground and it's reach from the seat) and find out the easiest way we can achieve this position and STILL have room to move the bars up or down or further away or closer to the rider. We establish this as a sort of middle point for the bar.

The reach to the bar is relatively simple -- there are only a couple variables. We need to know how much set back the seatpost gives us, which we can use some simple trigonometry from the seat height measurement to get. We factor in the effective top tube length, but using a measurement call the frame reach is more effective (this is the horizontal distance from the center of the bottom bracket to the middle point of the top of the headtube). And then the length of the stem (with a bit more trig to take into account the rise of the stem and the head tube angle), is the final piece to give us the overall reach of the bike.

The bar height has more variables to consider:

A simplified list of the parts that determine bar height are (from the ground up):

- radius of the wheel and tire

- fork axle to crown measurement

- lower headset cup stack height

- head tube length

- upper headset cup stack height

- spacers under the stem

- and stem rise or height

There are a lot of limitations in these parts:

- radius of the wheel and tire -- this doesn't change much unless you get a huge tire on there

- fork axle to crown measurement -- while there are variations in fork height, we often are stuck with what a given manufacturer provides

- lower headset cup stack height -- sometimes this is zero with inset headsets (as in the Wilier above)

- head tube length -- again, can't manipulate this after the fact

- upper headset cup stack height -- varies anywhere from 5mm up to 25mm

- spacers under the stem -- most modern forks, we're limited to 35 mm of spacers

- and stem rise or height -- while we can alter the stem rise, if we need more height, 35-40 degrees, depending on the length of the stem, is usually all we can get, and this isn't necessarily optimal for handling and aesthetics

So I can do all the math and run the variables for the bar height by hand, but I have created a couple of customized excel files to make estimating the bar reach and height a little simpler.

I can plug in certain parameters, like for instance that I want to keep the stem to only 12 degrees of rise and no more, and this will tell me what bar height I'll end up with.

I can use this to determine if the frame and bike the client is interested in will work -- if the head tube is the right length, but also is the headset integrated into the head tube or does it have external cups? Just this small variable change can make a big difference in whether a bike will work for someone.

Building a custom bike takes more knowledge about bike fit, handling and weight distribution, but it is much easier to get the bar position where we need it because I can manipulate the head tube to almost any length I want. This will ensure that I don't need to use an excessive amount of spacers under the stem, or a high rise stem, etc.

When dealing with a stock sized bike, we're essentially stuck with the size of bike that the manufacturer has created. Why not just get a frame the next size up to get a longer head tube if I need it? The problem with that is as the head tube gets longer, so does the effective top tube -- so the reach of the bike may then be too big.

It's a lot to keep track of, but we have to (yes, have to - at least in my shop) do our due diligence to get the best possible fit for our client. Anyone can build and sell a bike, but only the most particular professional can make sure that each and every client is as comfortable and efficient as possible on their bike.

There's more money in just selling bikes and getting them out the door, but we want to make sure that the bike will feel good in the shop, and 6 months down the road.

Check back later this week, and we'll have gone through all these variables and in the process of building a client's bike. We'll post details of the build as we go, including why we chose certain parts and accessories

Stay tuned

--J